Greda Metal specializes in the production of sheet metal stamped parts using high-capacity presses. The company owns a modern 3,000 m² production facility, fully equipped with the necessary infrastructure to support a large number of powerful presses. The entire production process is integrated on-site, along with the company’s administrative and management offices.

In addition to the main production hall, Greda Metal also has a modern 1,000 m² warehouse.

The production process is supported by a dedicated truck for material and goods transport, as well as three forklifts for internal handling and logistics.

In addition to the core production capabilities, the facility is equipped with auxiliary machines and devices, such as metal shears, spot welding machines, and other equipment. Compressed air is supplied by three large Atlas Copco compressors, ensuring continuous operation without energy-related downtime.

Greda Metal was founded in 1997 as a fully privately-owned company. The founders were Zoran Stanković, B.Sc. Civil Engineer (75% ownership), and Branko Dudić, B.Sc. Mechanical Engineer (25% ownership), who also served as company director from the very beginning.

Today, Greda Metal is 100% owned by Dragana Stanković.

Greda Metal operates a modern in-house toolshop for the production and maintenance of tools used in high-capacity press operations.

Thanks to our own toolshop, we ensure fast adaptation and high precision throughout the production process, guaranteeing the quality and reliability of every stamped part.

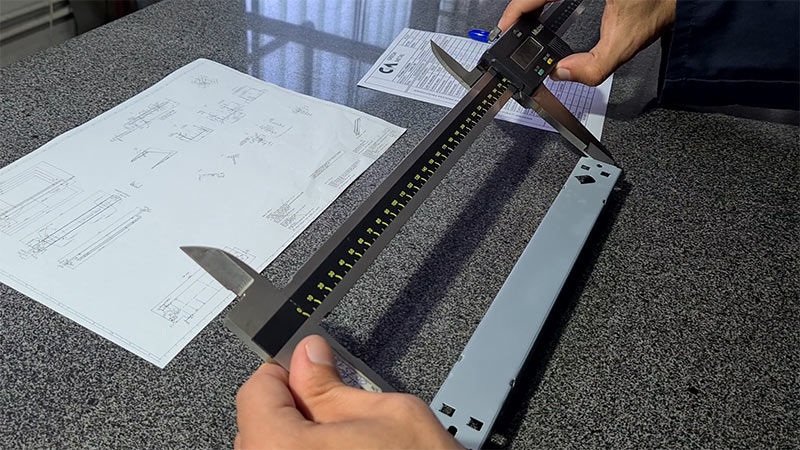

We place special emphasis on quality control at every stage of production.

Our expert team performs detailed measurements and inspections of all products and stamped parts to ensure that each finished piece meets the highest standards of precision and reliability.

Greda Metal employs a total of 50 employees, of which 38 are directly involved in production, while 12 are engaged in management and administrative tasks.

Our team includes 4 experienced mechanical engineers, whose expertise contributes to maintaining high standards of quality and precision in every project.

Our products are delivered to demanding markets across Europe. The largest client is the Slovenian company GORENJE, while a significant share of exports goes to companies in Germany, Austria, Hungary, and other countries in the region.

The company’s annual revenue amounts to €6,000,000.

Production of sheet metal stamped parts using high-capacity presses for the automotive, electrical, construction, and home appliance industries across Europe.